Replacing the axle gear

on a Bachmann Spectrum 2-8-0

If you have a large scale Bashmann Spectrum 2-8-0 "Connie", the chances

are that sooner or later you're going to have a problem with the axle

gear. The plastic they used is a bit brittle and prone to crack at the

hub and slip, or to lose teeth. Mine had both when I got it. If you are

the original owner Bachmann will fix it --- or more precisely replace

it with another one made of the same cheese as the failed one --- if

you aren't, or prefer to do it yourself AND you want it to stay fixed,

Northwest Shortline makes a much better replacement for the standard Bachmann gear. It is part number 2226-6. Yes, it costs about 3 times what the Bachmann gear does, but also seems to be worth every penny.

What you're going to need:

Small Phillips Screwdriver(s)

Jewelers screwdriver(s)

Nut driver or small Crescent wrench

needlenose pliers

sleeve, bit of 1/4" iron pipe or 3/8" deepwell socket

something to cradle the locomotive

shallow dish for screws

replacement gear

grease and oil

The first order of business is to fashion some sort of cradle to hold

the locomotive steady while it is upside down. I used a folded

comforter, but the lid of the original packing foam would probably work

even better - if you still have it.

There are 4 screws on the gear cover. These can be removed first. But

be extra careful you don't drop them down inside the boiler!

The next step is to remove the hex head screws holding on the siderods.

However, I only removed 6 and simply loosened the front ones to allow

the rods to slip off. The I laid them up over the pilot out of the way

Then you remove the 16 small screws holding the two bottom frame rails

in place. These are really small so a shallow dish to keep the screws in

is a good idea. then gently lift the brake rigging and fold it rearward out of

the way.

Then the axle simply lifts straight up and out. Be careful not to lose

the suspension springs or contact plungers! - Bachmann may not have

replacements for these anymore.

The counterweights are held on with a single screw through the end. You

only really need to take off one side. Remove the screw and gently pull

the counterweight straight off the end of the shaft. (If one side won't

come off, replace the screw and try the other - it doesn't martter

which one you remove)

With the counterweight removed, the bearing, spacer, wheel. and gearbox

bushing will simply slide off the axle. I laid them out on a

piece of duct tape as I removed them to keep track of them, and orient

which side was out.

Removing the old gear was really easy... it pretty much crumbled.

As you can see, the NWSL gear is designed slightly different, and

they say is less prone to crack or break.

It is an interference fit, and will need pressed on. I used a 3/8"

deepwell socket and a bench vice in place of an arbor press. But you

could probably just tap it on using some sort of simple sleeve and a

small hammer if you absolutely had to.

New gear installed. Then you just slide the parts back on the same way

they came off, make sure the counterweight is quartered the same as the

others, and replace the screw....

Now is probably a really good time to dig out the old grease and put in

new! Don't buy cheap grease, and no real need to skimp, either. That

little bitty tub of LGB grease has lasted me about 10 years so far.

This next part is where you earn your pay. It's a bit of a 3 handed job with only room for one.......

First you set the axle in the guides (the journal goes pin downwards towards the spring, the flat side is facing you).

Then with a toothpick or jewelers screwdriver slide the bronze bushings so they line up with the sides of the gearbox.

Next you gently lift the gearbox up to meet the axle.... and hold it in

place (I used a jewelers screwdriver as a lever in the slot on the

front end of the case) while you fit the cover. Note: It's MUCH easier

if you put the 4 screws in the cover before you put the cover in

place.... don't ask me how I know...

Then you reinstall the brake rigging, the bottom frame bars (Again, put

the screws in them first, too!) and then the siderods...

Last, lightly lubricate the siderods and valve gear

When it's done it will look just like when you started., except now the

locomotive should run for many years without another failure.

Removing the noise suppressor

While I was at it, I decided to remove the boiler to check the gearbox

screws and remove the noise suppressor since some folks report having

trouble with these using PWC (Crest/Aristo) power packs .

What you are going to need:

Small phillips screwdriver

Medium phillips screwdriver

needlenose pliers

soldering iron and electrical solder

shallow dish for screws

There are four v-e-r-y tiny screws holding the ashpan on. After the

ashpan is removed you can see the 4 mounting screws holding the boiler

to the chassis.

There's also a long screw at the front centered between the cylinders.

a screwdriver just fits or you can remove the pilot truck first for

easier access.

If yours is stock you will also have to remove some of the piping, the

tiny screw that attaches the Johnson bar reach rod to the reverse gear,

and

the brace rods from the smokebox. The wires at the firebox end are

pretty short and small -- so watch you don't pull and break them! Once

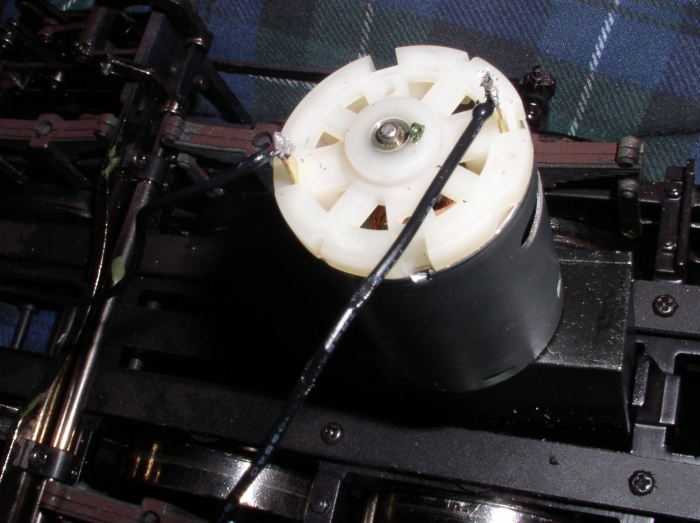

you have the boiler lifted off you can see the suppressor board mounted

to the end of the motor.

The noise suppressor is pretty easy to get rid of - just unsolder the

board from the motor, then the wires from the board, and re-solder the

two wires directly to the motor tabs in the same positions they were on

the board (being careful not to overheat the motor leads!).... If you

need to double check yourself, simply set the chassis up on a couple

blocks or rollers, apply power to the wheels, and make sure the

headlight is on bright when the wheels are turning forward.

Now is probably a good time to tighten

the screws in the side of the gearbox, too. Even if it isn't the reason you have it apart. Mine were all 1/4 to 1/2

turn loose...... Then you stuff the motor wires back into the hole in

the boiler, set the frame on the boiler, make certain you aren't

pinching any of those little wires in the firebox, and reinstall the 5

screws... then put the ashpan back on and replace the reach rod screw and piping. Then flip the

locomotive back on it's wheels.... and...... guess what? You did it!!!

See! I knew you could do it, too! All you needed was the confidence to try.

Return me to the AV pages